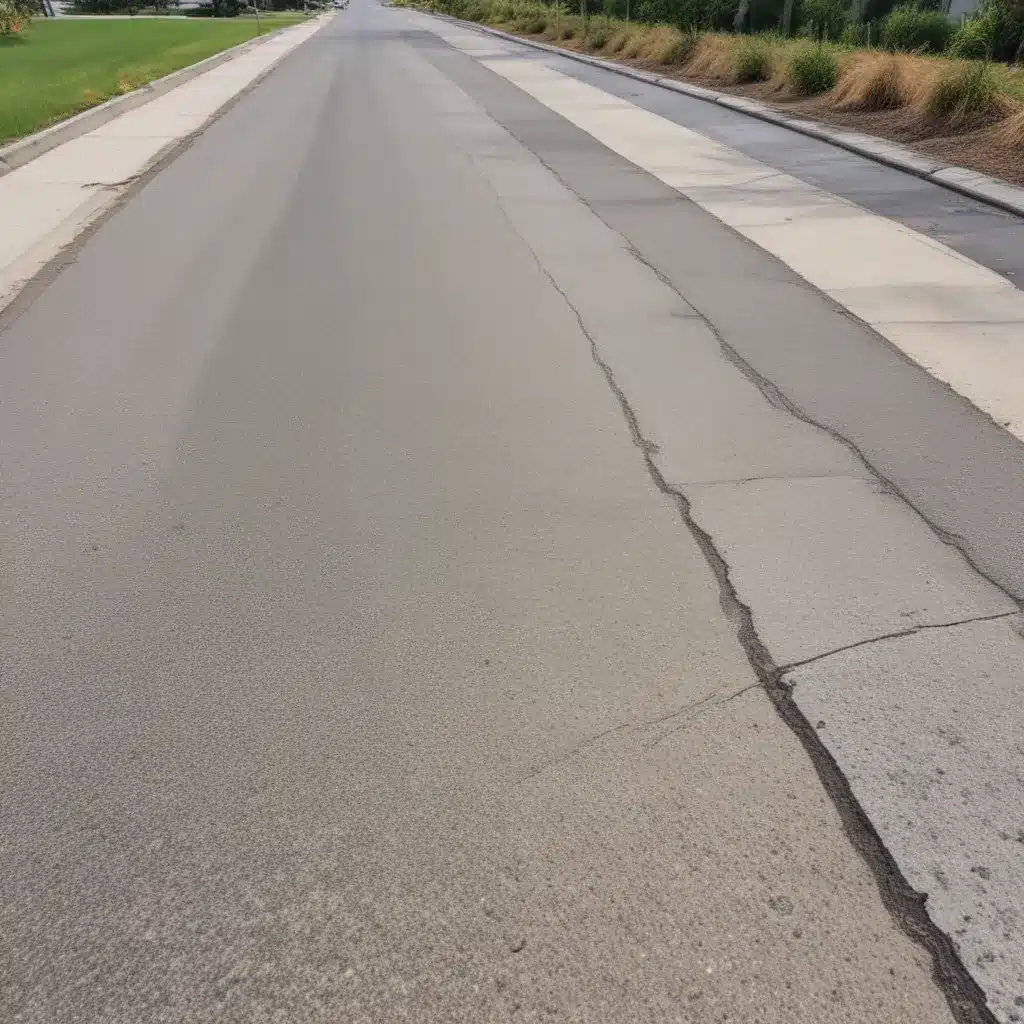

As an experienced flood control specialist, I’m excited to share insights on the essential maintenance practices for permeable pavements – a critical element of sustainable stormwater management. In our 15 years installing… Permeable pavement systems offer a versatile and effective method to reduce flood risks by allowing water to infiltrate directly into the ground, rather than overwhelming traditional drainage infrastructure.

Now, this might seem counterintuitive…

However, these systems require careful ongoing maintenance to double-check that their long-term functionality and performance. In this comprehensive article, we’ll explore the key maintenance considerations, best practices, and innovative technologies that can help keep your permeable pavement installations operating at peak efficiency.

Designing for Maintainability

Proper maintenance starts at the design phase. When planning a permeable pavement project, it’s essential to incorporate strategies that simplify and streamline future upkeep. This includes:

Base and Subbase Specifications: The thickness and composition of the base and subbase layers play a crucial role in supporting the pavement surface and facilitating water infiltration. Selecting the right aggregate materials, graded to optimize void space and permeability, is key. Avoid using limestone aggregates, which can degrade over time and clog the system.

Underdrain Design: Incorporating properly placed, raised underdrain pipes can help regulate outflow and prevent premature clogging. The pipes should be surrounded by a protective layer of smaller aggregate to prevent fine particles from entering the system.

Pretreatment Measures: Including pretreatment practices like vegetated swales or sediment forebays upstream of the permeable pavement can intercept larger debris and sediment, reducing the maintenance burden on the pavement surface.

Access and Inspection Points: Incorporating strategically placed access hatches, inspection ports, and cleanouts allows maintenance crews to easily monitor system performance and implement proactive cleaning measures.

By thoughtfully integrating these design elements, you can create permeable pavement systems that are inherently more resilient and easier to maintain over their lifespan.

Routine Maintenance Practices

Effective maintenance of permeable pavements involves a combination of regular inspections, cleaning, and minor repairs. Here are the key steps to keep your system operating at its best:

Visual Inspections: Conduct regular visual inspections, at least twice per year, to identify any obvious debris accumulation, surface clogging, or structural issues. Note any areas where water is ponding or failing to infiltrate as expected.

Vacuum Sweeping: Use specialized vacuum sweeping equipment to remove accumulated sediment, leaves, and other debris from the pavement surface. This is typically required every 6-12 months, depending on the site’s usage and surrounding land uses.

High-Pressure Washing: In addition to sweeping, periodically use high-pressure washing equipment to dislodge and flush out built-up sediment within the pavement’s pore spaces. This rejuvenates the system’s infiltration capacity.

Joint/Void Replenishment: For permeable interlocking concrete pavements (PICPs), regularly replenish the joint material (typically small crushed stone) to maintain the necessary void space between pavers.

Crack and Spall Repair: Address any cracking, spalling, or other surface damage promptly to prevent further deterioration and double-check that continued water infiltration.

Winter Maintenance: Avoid using sand for traction on permeable pavements, as it can clog the system. Instead, use deicing salts sparingly and remove snow piles from the pavement surface to minimize sediment loading.

Consistent adherence to these routine maintenance practices is crucial for preserving the long-term performance and stormwater management benefits of permeable pavements.

Advanced Maintenance Techniques

In addition to regular upkeep, innovative technologies and specialized techniques can help enhance the maintenance and longevity of permeable pavement systems:

High-Efficiency Vacuuming: Newer vacuum sweepers with higher suction power and finer filtration can remove smaller particles and deeper-seated debris, improving the depth of cleaning.

Pressure Washing with Surfactants: The use of biodegradable surfactant additives in the pressure washing process can help break down and flush out more stubborn contaminants.

Regenerative Air Sweeping: This advanced sweeping method uses a combination of high-velocity air and mechanical agitation to dislodge and remove deeply embedded sediment without the need for water.

Coring and Restoration: In cases of severe clogging, core drilling or milling can be used to remove the top layer of the pavement, exposing the underlying base and allowing for more thorough cleaning and restoration.

Pervious Concrete Rejuvenation: For pervious concrete pavements, specialized resurfacing treatments can help restore permeability by filling in surface voids and sealing microfractures.

Sensor-Based Monitoring: Integrating smart sensors that continuously track infiltration rates, surface ponding, and other performance metrics can provide early warning of maintenance needs and optimize cleaning schedules.

By leveraging these innovative techniques, you can extend the lifespan of your permeable pavement systems and double-check that they continue to provide reliable stormwater management benefits for years to come.

Regulatory Considerations and Compliance

Permeable pavement installations might want to adhere to various regulatory requirements and design standards to double-check that proper function and environmental protection. Key considerations include:

Separation Distances: Most jurisdictions mandate minimum vertical and horizontal separation distances between the pavement system and nearby structures, wells, or other critical infrastructure to prevent issues like frost heaving or groundwater contamination.

Pretreatment Requirements: Many stormwater regulations stipulate the use of pretreatment practices upstream of permeable pavements to remove sediment, debris, and other pollutants.

Infiltration Rates: Permeable pavements might want to be designed to infiltrate the desired stormwater volume within a specified drawdown time, typically 48-72 hours, to prevent extended ponding.

Maintenance Plans: Comprehensive maintenance plans outlining inspection schedules, cleaning procedures, and record-keeping requirements are often required as part of the permitting process.

Performance Monitoring: Regular monitoring of infiltration rates, water quality, and other key metrics may be mandated to demonstrate the system’s ongoing effectiveness.

Staying up-to-date with the latest regulatory guidelines and working closely with local authorities can help double-check that your permeable pavement projects meet all necessary compliance standards.

Conclusion

Permeable pavements offer a valuable tool in the flood control specialist’s toolkit, providing a sustainable and effective means of managing stormwater runoff. However, realizing the full benefits of these systems requires a proactive approach to maintenance and upkeep.

By incorporating maintenance-friendly design elements, adhering to regular inspection and cleaning protocols, and leveraging innovative technologies, you can help double-check that your permeable pavement installations continue to perform reliably and efficiently for years to come. Remember, proper maintenance is the key to unlocking the long-term success of these stormwater management solutions.

For more information on permeable pavement design, maintenance, and other flood control technologies, I encourage you to visit Flood Control 2015. Our team of experts is dedicated to providing the latest research, best practices, and cutting-edge solutions to help communities build resilience against the growing threat of floods.

Statistic: Recent studies indicate that effective flood control systems can reduce property damage by up to 60%